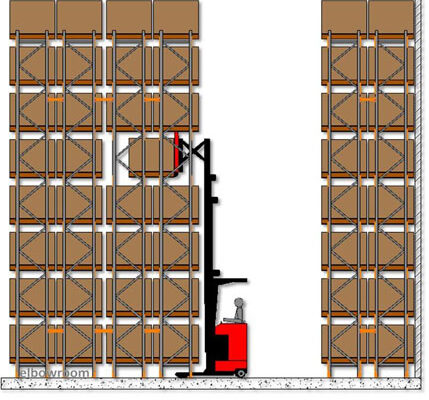

If you’re struggling for storage space in your warehouse, now might be the time to switch its configuration to a double deep selective racking system which enables you to access two rows of stacked pallets from the same aisle. It does, however, also mean that you may have to remove the first pallet to access the pallet behind, meaning it’s important to consider your options carefully before investing in a new racking system.

Here at Elbowroom, we stock all the racking, shelving and storage solutions you need to maintain an orderly and efficient warehouse. In addition to supplying the highest-quality solutions on the market, we can also handle the design and installation on your behalf, making us the only contact you need to transform your warehouse from an unorganised storage space into a practical workplace.

Advantages and disadvantages of double deep pallet racking

If you need to maximise your warehouse’s storage capacity, our double deep pallet racking solutions might be perfect for you. Depending on the layout of your warehouse, pallet racking can essentially double the amount of storage space you have. However, while there are many advantages of double deep pallet racking, you should be aware they’re not the most suitable option for all environments.

As a general rule of thumb, you should opt for a pallet racking system if storage space is your main concern. If, however, easy access to warehoused goods is your main priority, you may want to investigate other options. Find out which storage solutions are most suitable for your work environment by calling our professionals.

Learn more about double deep pallet racking advantages

Elbowroom is your one-stop-shop for all pallet racking and storage solutions. We can deliver our products on a nationwide scale. If you run a business in Brisbane, you can trust our professionals to handle the design and installation from start to finish, all for a high-value price you won’t believe. Call us today for more information and advice.