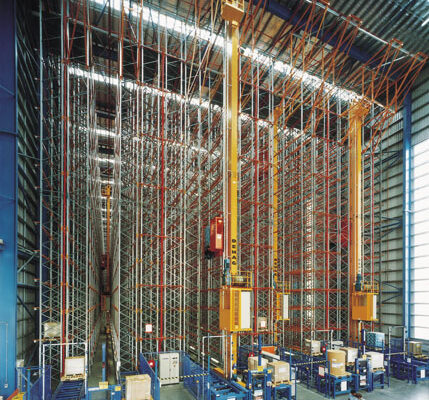

We recommend state-of-the-art Automated Storage and Retrieval Systems (AS/RS) for major distribution centres and large-scale operations.

AS/RS utilises intelligent robotic cranes and shuttles. They store and retrieve inventory independently, to and from locations dictated by the connected warehouse management software. With unmatched throughput capacity and inventory control, our AS/RS solutions allow seamless scalability as your business grows.