Pareto principle

https://en.wikipedia.org/wiki/Pareto_principle

So let’s have a quick look at how Pareto’s 80/20 principle RULES in a typical warehouse operation.

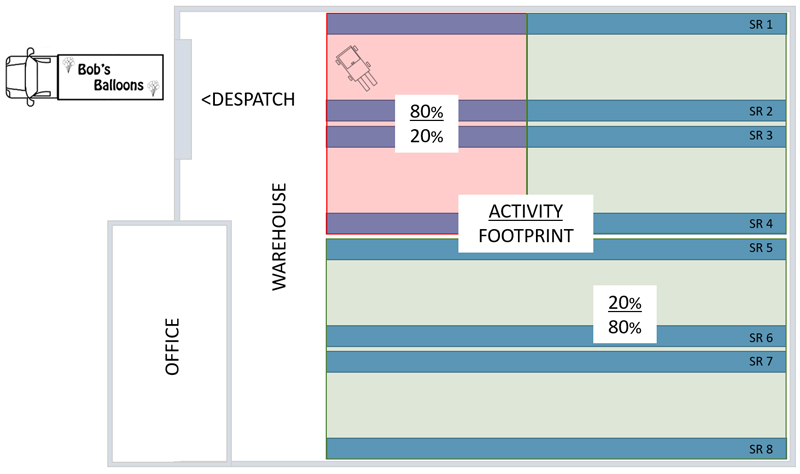

Stock Location

This seems simple and obvious – store the fast movers closer to the despatch exit.

There are plenty of smart Warehouse Management Systems (WMSs) out there these days and typically they will promote or suggest put-away locations based on movement-over-volume principles. Not surprisingly, this often results in the products which represent an average 80% of activity through the exit door, will occupy the 20% of warehouse space closest to that door. Pareto’s 80/20 principle RULES.

This also results in 80% of the warehouse space being occupied by products which represent an average of 20% of the activity. Pareto’s 80/20 principle RULES again. Is there a challenge here?

Inventory Value

So now, when we look at Inventory Value in the above warehouse scenario, we see that typically the inventory value represents 80% tied up in slow movers and 20% not so tied up in the fast movers.

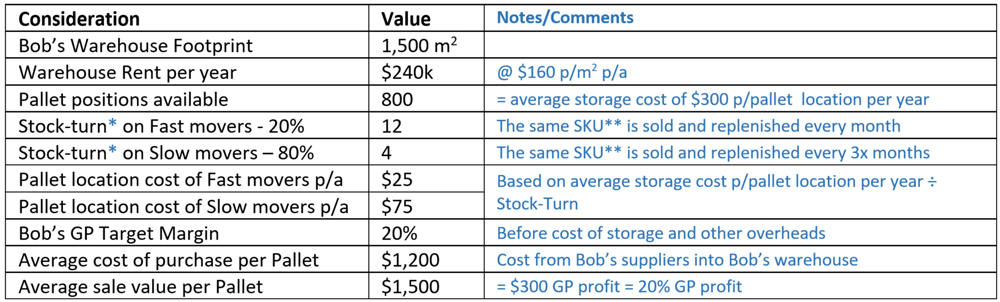

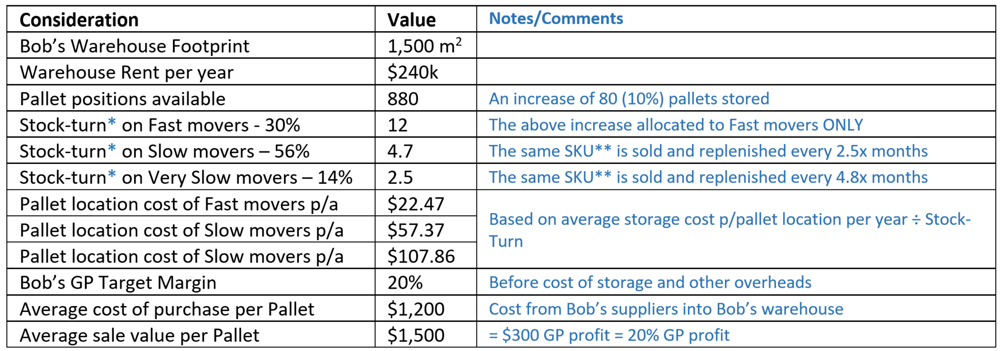

How about we stay with Inventory Value to dig a little deeper and consider some other issues. We will use a fictional business with some sample numbers to see what comes from them.

Bob’s Balloon Business (Sample numbers):

*The simple way of looking at Stock-turn is in its name – A stock turnover formula is the ratio that measures the number of times inventory is sold or consumed in a given time period. In our sample case, that period is 12 months. There are lots of more complicated formulas available on the net – if needed, just google Stock Turn!

** A SKU is a unique Stock Keeping Unit

We now have the numbers from Bob’s Balloon Business, so let’s take a look at what the cost of Bob’s inventory is, or the “cost of sale” proportioned to Bob’s inventory and Stock-turn.

Bob makes $300 per pallet GP from the sale of his Slow Movers. After cost of storage ($75), Bob’s profit is reduced to $225, or 15% of Sale Price

Bob makes $300 per pallet GP from the sale of his Fast Movers. After cost of storage ($25), Bob’s profit per pallet is reduced to $275, or 18.33% of Sale Price

Is there a challenge here?

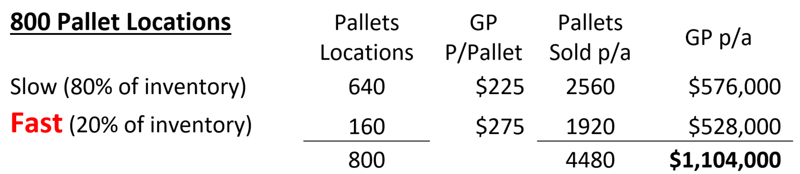

Footprint Management

Managing storage footprint is critical to optimising warehousing costs and maximising margins on sales of stored products.

Challenging Pareto’s 80/20 principle may be a place to start..

Let’s say, Bob’s seasonal sales have both very high and very low movers at different times during the year. During and around December for example, Bob’s very fast movers are balloons themed as ‘Merry Christmas’ and ‘Happy New Year’. While at the same time ‘Happy Birthday’ balloons move very slow along with plain ‘Pink’ and ‘Blue’ balloons. Bob realises that efficiency and therefore cost gains are possible through having a warehouse footprint which can offer more optimisation to the seasonal demands of the business.

So Bob contacts his go-to storage expert at Elbowroom and together they work out a solution to the challenge.

A little flexibility is required as demands change throughout the year. Adding up all the other considerations – too many to mention here – they decide to invest in some Drive-In rack to store the very slow moving, seasonal SKUs, while continuing with Selective Rack for the fast movers and the average slow movers.

Bob has now added these dynamics to the warehouse pallet storage system where seasonal optimisation can be managed and costs optimised.

Summary

While Pareto’s 80/20 principle often rules in a typical storage or warehouse environment, it is worth challenging.

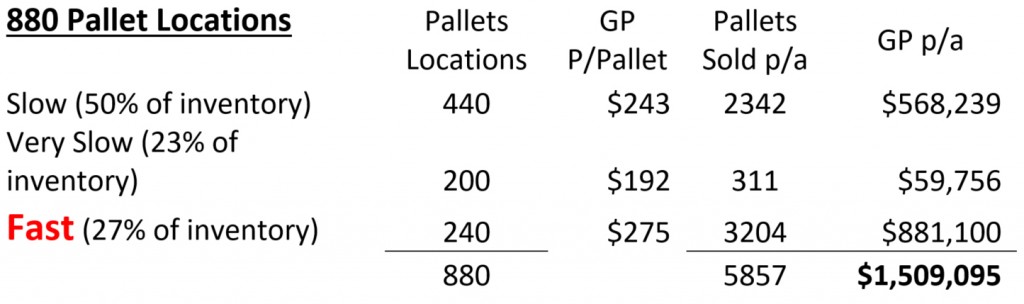

In Bob’s Balloons’ scenario, Bob has challenged Pareto’s principle and has..

- Increased overall pallet storage capacity;

- improved the inventory ratio between fast movers and slow movers;

- maintained the same number of slow movers – nothing lost;

- increased average profit per pallet of balloons by over $10;

- improved output of the highest GP SKUs resulting in substantial profit gains;

- made all improvements without increasing overall footprint or cost of real estate.

Why not help us to help you?

Just call your go-to storage expert at Elbowroom NOW!

1800 810 331

mark.althaus@elbowroom.com.au