If you’re a growing business or looking to elevate your goods off the floor for the first time, this guide will help you navigate the complexities of pallet racking. Understanding the dimensions and sizes of pallet racks is crucial to ensure a safe and efficient storage solution.

What is Pallet Racking?

Pallet racking is a storage system designed to store pallets either within the rack or on/above the floor. The most commonly used type of pallet racking today is “Selective Rack” (SR), which typically comprises 840mm deep end frames. Although the selection process for SR might seem straightforward, there are crucial considerations to avoid potential pitfalls.

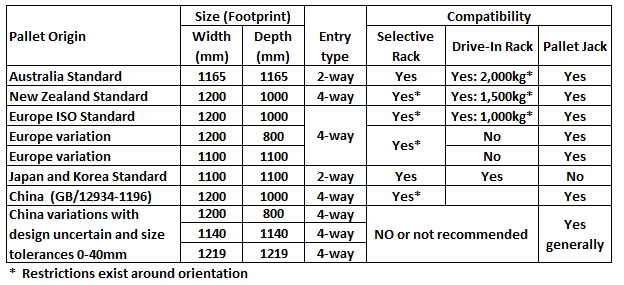

Understanding Pallet Dimensions

Australian Standard Pallets

- Dimensions: 1165mm x 1165mm

- Load Capacity: 2,000kg

- Standard: AS4068-Flat pallets for materials handling

Import Pallets

Not all pallets conform to Australian standards. Import pallets may require additional rack accessories to prevent collapse or damage, which can also pose safety risks to operators.

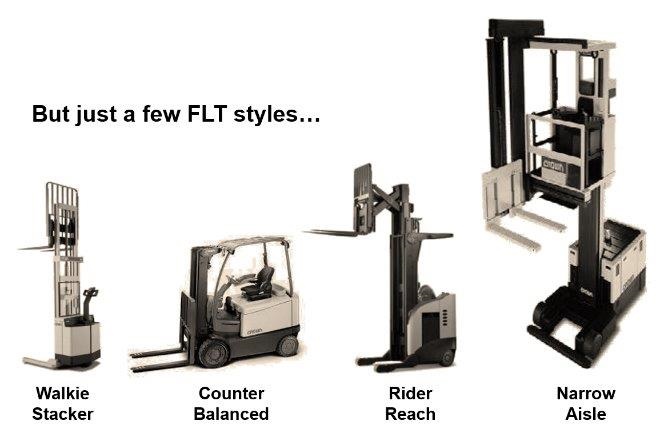

Forklift Considerations

Selecting the right forklift is as important as choosing the right pallet rack. Here are some factors to consider:

Lift Capacity

Ensure the forklift’s lift capacity meets your storage needs to the full height of the rack. Note that lift capacity decreases as the load centre height increases.

Lift Height

Fork tines should lift at least 225mm above the highest horizontal load support (beam) to allow comfortable lift and put-away operations.

Turning Radius

The forklift’s turning radius should suit the effective aisle space, considering pallet overhang and reducing steel-to-steel aisle clearance.

Reach and Stabilisers

Fork reach and stabilisers can affect forklift operation. Non-standard beam lengths might be necessary for forklifts with outside stabilisers. Proper rack design and expert advice are essential to match forklift and rack designs accurately.

Designing the Rack

When designing your pallet rack, consider both current needs and future requirements. Ensure your rack design is safe and can handle heavier loads when necessary. Obtain a signed as-built Engineer’s certificate from your rack supplier to confirm the rack’s load capacity and safety.

Learn more about pallet rack designing

Location and Installation

The location of your pallet rack within the warehouse affects its operation and safety. Here are some placement guidelines:

- Wall Clearance: Place racks at least 200-300mm away from walls to prevent pallets from contacting the wall.

- End Clearance: Maintain a 300-400mm clearance from walls or obstructions at the ends of the rack for forklift manoeuvrability.

- Indoor Use: Standard SR racks are designed for indoor use. Outdoor racks must comply with the Building Code of Australia and local environmental regulations.

Ensuring Safety and Compliance

Ensure your pallet rack complies with AS4084 standards. Each rack should have a load sign labelled and endorsed by a legitimate supplier. When purchasing used racks, verify they can be signed off by an authorised party to avoid counterfeit brands.

Getting Expert Advice

For tailored advice on pallet racking and warehouse storage solutions, contact the experts at Elbowroom. We provide free advice and can help design a system that meets your current needs and future plans.

Contact Information

Elbowroom

- Phone: 1800 810 331

- Website: Elbowroom

Ensure your pallet racking system is safe, efficient, and compliant by consulting with professionals. With the right guidance, you can optimise your warehouse storage and avoid costly mistakes.