Business spaces and needs vary. We understand this, so we have made it our job to know all there is to know about every type of pallet racking Brisbane businesses could want. With this knowledge, our team of experts can give you helpful, accurate advice for creating the ideal storage solution for your company.

Pallet Racking Systems & Storage Solutions

At Elbowroom, we have an extensive range of pallet storage solutions available. Whatever your warehouse requirements, you are sure to find what you need right here with us. We offer a selection of pallet racking systems to suit a variety of purposes.

Choose the Right Rack for You

We offer a selection of pallet racking systems to suit a variety of purposes.

AS/RS

Push Back Pallet Rack

Pallet Live Racking

Pallet Runner ®

Narrow Aisle Racking

Selective Pallet Racking

Double Deep Racking

Drive-In Racking

Solutions for All Your Pallet Racking Needs

At Elbowroom, we’ve been providing custom pallet storage solutions across Australia since 1973. Whether you need to maximise warehouse space, improve picking and restocking, or keep products secure, our top-notch pallet racking and shelving solutions can make it happen.

Heavy-Duty Pallet Racking Systems Built to Last

Our pallet racking and long-span shelving systems are made for maximum durability. They also provide flexibility and functionality, regardless of the size or scope of your operations. We offer both high-quality boltless and widespan racking options, so you can create a custom storage solution suited to the dimensions and layout of your warehouse and inventory.

Selective Pallet Racking for Versatile Storage

Selective pallet racking is one of our most popular options. It allows direct forklift access to every pallet stored in the system. This makes it ideal for a wide variety of applications and inventory. We can help you improve your racking storage layout for maximum space, efficiency, and order fulfilment.

Make the Most of Space With Narrow Aisle Racking

When floor space is at a premium, narrow aisle pallet racking systems allow you to improve storage density. By reducing aisle width throughout the storage layout, we can help you install more pallet positions in the same square space as a standard pallet racking system.

Our narrow aisle storage solutions are ideal for retail stores, e-commerce, and any business managing a high volume of SKUs. Enhanced storage allows you to keep up with changing inventory needs.

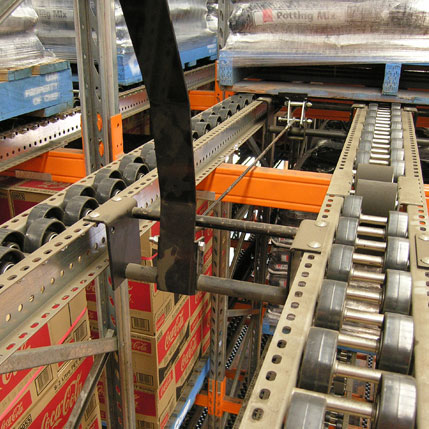

First-In-First-Out Pallet Flow With Live Racking

To take warehouse efficiency to the next level, many customers choose our pallet live racking system. It uses gravity roller or wheel flow track lanes to enable easy access to stored pallets, while making the most of storage capacity.

Based on the proven first-in-first-out (FIFO) principle, pallet live racking eliminates the possibility of expiry or turnover-related losses. The gently sloped wheel and roller flow lanes allow pickers to retrieve individual pallets as needed without disrupting the flow of upstream pallets waiting in the lanes.

Pallet live racking is ideal for any business where inventory freshness and high order accuracy are critical.

Next-Generation Automation With ASRS

We recommend our state-of-the-art Automated Storage and Retrieval Systems (ASRS) for major distribution centres and large-scale operations.

ASRS utilises intelligent robotic cranes and shuttles. They store and retrieve inventory independently, to and from locations dictated by the connected warehouse management software. With unmatched throughput capacity and inventory control, our ASRS solutions allow seamless scalability as your business grows.

Drive-In and Push-Back Racking

Where dense, large-volume storage is critical, such as in cold storage freezer environments, we offer tailored solutions like drive-in and push-back racking.

Drive-in racking enables multiple pallets to be loaded deep into each bay on telescopic rails, maximising storage density for products with high cubic volume. Push-back racking uses moveable carts to similarly store pallets, while allowing simple last-in-first-out (LIFO) access to the most recently stored fast-moving items.

End-to-End Pallet Racking Solutions

Whether you need us to completely overhaul your warehouse strategy or simply provide guidance on racking upgrades, we will deliver first-class solutions.

Please reach out for a free, no-obligation quote for your pallet racking storage solution needs; we’re confident you’ll love the Elbowroom difference!

[Call Now On 1800 810 331]

Only the Best

We use Colby racking when we complete any pallet racking job. ColbyRACK is the biggest, strongest and safest Australian-manufactured pallet racking product available. That statement cannot be honestly made in relation to any other rack brand sold in Australia today.

While Colby products are supported by Elbowroom in part because of their strength and safety record, we also support them because they really are made in Australia. They are manufactured by a great team at the Belrose factory in NSW. This product is competitively priced and offers the best value-for-money outcomes to our customers. Members of the Colby design and engineering team are very talented and enjoy worldwide recognition of their expertise and qualifications in their field.

The Colby brand really does meet the Australian and European Standards that Colby says it does – and we will prove this by supplying you evidence with every individually designed ColbyRACK we supply or endorse.

Check out the pallet storage solutions and options below to find out what will best suit your requirements. Our expert team is also fully qualified to carry out pallet racking audits, repairs and installations. Trust us from start to finish with your pallet racks. You can enquire through our email system or just give us a call on 1800 810 331.

FAQS

What are the different types of warehouse pallet racking systems?

At Elbowroom, we offer a variety of warehouse pallet racking systems and shelving solutions to meet your storage needs. Here are the different types of racking systems available:

- Automatic storage and retrieval system (AS/RS)

- Push back pallet rack

- Pallet live racking

- Pallet Runner®

- Narrow aisle racking

- Selective warehouse pallet racking

- Double deep racking

- Drive-in racking

What type of pallet racking system do I need for my warehouse?

The right type of pallet racking your warehouse needs depends on various factors. Here are a few considerations to keep in mind:

- Warehouse layout — Consider the layout of your warehouse and the amount of floor space available. Narrow aisle racking may be an excellent option to maximise your pallet racking in your warehouse.

- Product type and weight — Choose a racking system that can support the weight and dimensions of the stock you want to store.

- Frequency of access — If you need frequent access to your stock, a selective warehouse pallet system might be a good choice. If you need high-density storage and access is not as frequent, a drive-in or push-back system might be more suitable.

- Budget — Consider your budget when choosing a warehouse pallet racking system. Some systems, like automatic storage and retrieval systems (AS/RS), can be more expensive but offer greater efficiency.

Contact us today for expert advice on the right warehouse pallet system for your business.

How much weight can pallet racking systems hold?

The weight capacity of warehouse pallet racking systems can vary based on several factors, including the type of system, the size and material of the beams and columns.

Our team of experts has dedicated themselves to gaining comprehensive knowledge about every type of pallet racking that businesses may require. By leveraging this knowledge, we can provide you with precise and valuable guidance in creating an optimal storage solution for your company.

Are warehouse pallet racking systems safe?

At Elbowroom, we only offer high-quality warehouse pallet racking systems designed and manufactured to meet Australian industry safety standards.

You need to also ensure that the warehouse pallet racking system is properly installed, and to regularly inspect the system for any signs of wear or damage. Additionally, it’s essential to adequately train employees on how to safely use the racking system and follow all relevant safety guidelines.

Ready to streamline your storage systems?

Request an obligation free consultation with our storage solution specialists & let us help tailor a solution around your specific needs

Brendan Reeve

Porter Equipment